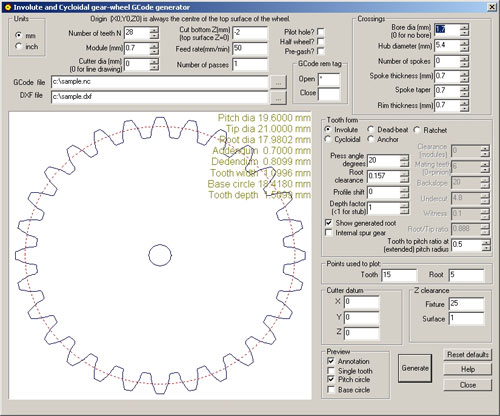

More about that later… Amended sprocket template These lines dissected each tooth in two to provide a centre point to a 13mm circle which is the size of the each tooth. If I’ve confused you by swapping sprockets, don’t be. The tooth and gap dimension are the same but the number of teeth is different. In other words both the sprockets you see on this page will run on the same chain. With a template glued to a suitable piece of timber (I used MDF by plywood would be stronger and more durable), Matthias suggests using a bradawl to punch the marked drill centres on his templates ready to dill out material. The problem is using a bradawl to prone to mistake. A simple slip would easily mess things up. I guess I’m not as skilled as he is… plus the inaccuracies in the print meant I couldn’t rely on the positions of such points too much. #WOODEN GEAR TEMPLATE GENERATOR DOWNLOAD PLUS# So I decided to centre mark with a bradwal of my own. I placed a simple panel pin my drill chuck, turned on my angle grinder and drill and by carefully bringing the two together I was able to make a very sharp metal bradawl pin for my drill press. I clamped a scrap of timber to the drill table. I carefully marked the centre of my sprocket-work, drilled a 2mm hole through the centre and drilled down a little further into the clamped wood (deck). With everything removed from the drill press, the 2mm drill is pushed into the sprocket and then into the deck – making a simple compass jig. With careful adjustment I was able to position the point of my bradawl pin to be exactly on the one of the drilling points on the template. This meant that with the lightest of pressure I was able to mark a hole for drilling without fear of slipping. Remember, it’s necessary to mark all the centre marks on the template, the ones for drilling and the ones that we add ourselves! Turning the work on the compass jig meant that each subsequent mark I made was always going to be same distance from the centre and it made lining up these points much easier. With the drilling points marked it was a simple matter of placing a 2mm drill bit into the press and boring out a few holes pilot.

Obviously you only need to pilot drill the daps between the teeth (not the teeth themselves – even then we marked a centre point with the bradwal pin). I removed the work and sanded the burs from the underside before adding a step drill to the chuck. This maxed at 12mm which is prefect for my needs here and it makes easy work of this process. The drilling is easy and the technique simple… Apply very little pressure the work and gently lower the setp drill. The bit will try to align and centre itself on the pilot hole below – so let it. #WOODEN GEAR TEMPLATE GENERATOR DOWNLOAD DOWNLOAD#.#WOODEN GEAR TEMPLATE GENERATOR DOWNLOAD PLUS#.#WOODEN GEAR TEMPLATE GENERATOR DOWNLOAD HOW TO#.

0 kommentar(er)

0 kommentar(er)